Does the quality of the Pure Nicotine in vapes and white pouches matter?

Does the quality of the Pure Nicotine in vapes and white pouches matter?

The European Tobacco Products Directive (TPD) was a case of good news, bad news. The e-cigarette and e-liquid industry was given a formal legal basis to grow and invest, albeit with limitations on maximum nicotine levels, bottle size and tank size in mods, but in general it worked out and was beneficial to the industry. While some compounds were explicitly blacklisted (acetaldehyde, for example), the quality of ALL ingredients, as defined in the TPD, was not as definitive on standards as it could have been.

The industry defaulted, for the lack of other guidance, for EP or USP pharmaceutical monographs for the main ingredients, namely nicotine, vegetable glycerine and propylene glycol. Vegetal glycerine and propylene glycol are used as carriers in both the vape and pharmaceutical industry, while nicotine is an active ingredient (pharmacologically active).

"Member States shall ensure that: [..] (d) only ingredients of high purity are used in the manufacture of the nicotine-containing liquid. Substances other than the ingredients referred to in point (b) of the second subparagraph of paragraph 2 of this Article are only present in the nicotine-containing liquid in trace levels, if such traces are technically unavoidable during manufacture;”

European Tobacco Products Directive (EUTPD) (2014/40/EU)

The industry defaulted, for the lack of other guidance, for EP or USP pharmaceutical monographs for the main ingredients, namely nicotine, vegetable glycerine and propylene glycol. Vegetal glycerine and propylene glycol are used as carriers in both the vape and pharmaceutical industry, while nicotine is an active ingredient (pharmacologically active).

All ingredients, to some extent, contain impurities and the EP or USP pharmacopoeia set limits for these impurities based on daily exposure levels or No Observed Adverse Effect Level (NOAEL) to fixed daily dose dosage pharmaceutical forms (i.e., patches, gums, etc.). The daily exposure limits are “by design” broad and for light or normal vapers they are unlikely to be a problem, but heavy vapers may exceed even these buffer limits, as vaping is not a fixed daily dose; that said, there is no great story or concern here, as the daily limits are unlikely to be exceeded when using pure EP/USP grade nicotine.

So, if EP/USP nicotine is ‘fit for purpose’, why did Alchem decide to invest in the development and production of its NicSelect™ Nicotine 3.0, which far exceeds the monograph’s standards, with zero impurities ? The answers are important for e-liquid and pouches manufacturers and are two-fold (i) organoleptic properties and (ii) stability.

The exceptionally high purity (zero impurities) of NicSelect™ Nicotine 3.0 is achieved using additional purification phases and special technologies that remove the organic and inorganic compounds, sometimes only present in ppm and ppb, that give or cause the development of “off odours” in nicotine; typical examples of taste and smell issues reported are rubber, petrol or a fishy odour and taste.

Nicotine oxidation: how it affects the quality of finished products

The smell and taste of petrol is usually explained by the fact that low-cost nicotine production uses petrol or similar solvents for the initial extraction of nicotine from the tobacco leaf. The rubber or fishy odour and taste is indicative of unwanted compounds and that oxidation of the pure nicotine has started and is accelerating.

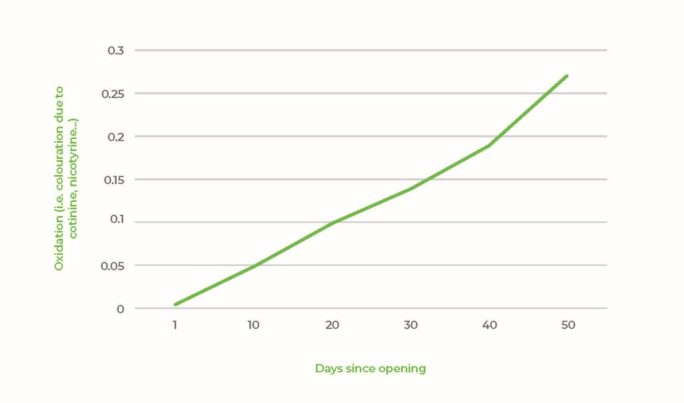

Nicotine “loves” to oxidize, it is the “nature of the beast”, but oxidation is also exponential and accelerates once initiated; the purer the nicotine the slower oxidation is to start. As a result, nicotine dilutions, nicotine salts, e-liquids and nicotine pouches made with ultra-pure, ultra-clean nicotine like NicSelect™ Nicotine 3.0 stay in the best condition for consumption for longer, meaning fresher e-liquids and whiter pouches.

It is easy to illustrate the oxidation phenomenon with a simple experiment: we left pure nicotine samples from different manufacturers exposed to light, heat (room temperature) and oxygen for three weeks. After three weeks, the NicSelect™ Nicotine 3.0 (far right, sample R116) remains clear as water while the other, less pure but compliant with EP/USP monographs, nicotine samples have oxidised and the rate of oxidation is accelerating.

Comparison of Alchem NicSelect™ Nicotine 3.0 (Sample R 1166) with other EP Nicotine samples

The samples were left exposed to light and air at room temperature for three weeks – the Alchem NicSelect™ Nicotine 3.0 (far right) remained clear and stable whereas the other samples quickly oxidized turning yellow and then yellow to brown.

Ultra-clean, ultra-pure, ultra-stable: NicSelect™ Nicotine 3.0

Alchem achieves the ultra-clean and ultra-pure quality of NicSelect™ Nicotine 3.0 by investing in unique manufacturing equipment, processes and technologies developed at our Research & Development (R&D) centre in Ballabgarh. Product consistency is achieved through the strict application of pharmaceutical GMP, to ensure that every batch is of the same perfect quality – no ifs or buts – every batch is the same.

While the additional processing and technologies used to make ultra-pure, ultra-clean nicotine comes at a loss of production yield and a higher production cost, the actual cost difference between NicSelect™ Nicotine 3.0 and standard nicotine EP/USP is relatively modest and over the past 12 years it has become the nicotine of choice for a majority of manufacturers of e-liquids and pouches in Europe, the most quality-focused territory in the global nicotine market.

Purchasing managers appreciate the price to quality combination, production managers appreciate the quality and consistency, and vapers appreciate the clean taste of NicSelect™ Nicotine 3.0 – win, win and win. At the end of the day, accountants and production managers know that producing 500,000 bottles of e-liquids with a lower cost nicotine does not save a penny if the batch has a fishy or other odour and has to be binned and remade or the batch is put on sale and market and brand reputation lost. It is an old adage, but it is not quality that costs, but a lack of quality.

Nicotine impurity profile and organoleptic quality and stability

Impurities are important not only for toxicology and safety, but the defined and total impurities are related to the organoleptic properties of nicotine for vaping or for nicotine pouches.

Some compounds also indicate that nicotine is oxidised or undergoing oxidation. Oxidation is like a runaway train: once started, it picks up speed and accelerates exponentially, but if you start with low levels of oxidation products, the oxidation process is inhibited and slowed.

Defined impurities by EP/USP Monographs

| Related Substances (by HPLC) | EP/USP Spec | Standard EP Nicotine | NicSelect™ Nicotine 3.0 |

| Impurity A (Anatabine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity B (Nicotyrine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity C (Cotinine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity D (Myosmine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity E (Nicotine-n-Oxide) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity F (Nor-Nicotine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Impurity G (Anabasine) | NMT 0.3% | < 0.2% | < 0.05% below LOD |

| Unspecified Impurities | NMT 0.10% | < 0.05% | < 0.05% below LOD |

| Total Impurities | NMT 0.8% | < 0.6% | < 0.05% below LOD |

Table 1 – EP/USP related substances and average tests results for Standard EP Nicotine and NicSelect Nicotine 3.0.

In addition, the Alchem NicSelect R&D team carried out experimental tests to compare NicSelect Nicotine 3.0 and Standard EP Nicotine (see Table 1) and identified a series of components (see Table 2) which, when present in amounts greater than 0.3% individually or added together in amounts greater than 0.4%, cause or accelerate oxidation or an unpleasant and pungent odour.

Undefined components that cause or accelerate oxidation or an unpleasant and pungent odour

| Smell Causing Components (by GC) | Sample of EP Nicotine with unpleasant odour | NicSelect™ Nicotine 3.0 |

| Comp. A | 0.8 | 0.1 |

| Comp. B | 0.4 | 0.1 |

| Comp. C | 0.2 | 0.08 |

| Comp. D | 0.4 | 0.1 |

| Comp. E | 0.1 | 0.05 |

| Comp. F | 0.2 | 0.1 |

Table 2 – Smell causing components.

Note: the components that generate odours are not the same as impurities but they increase as the nicotine and impurities oxidize resulting in the development of colour, unpleasant odours and unpleasant taste.